Aerostructures

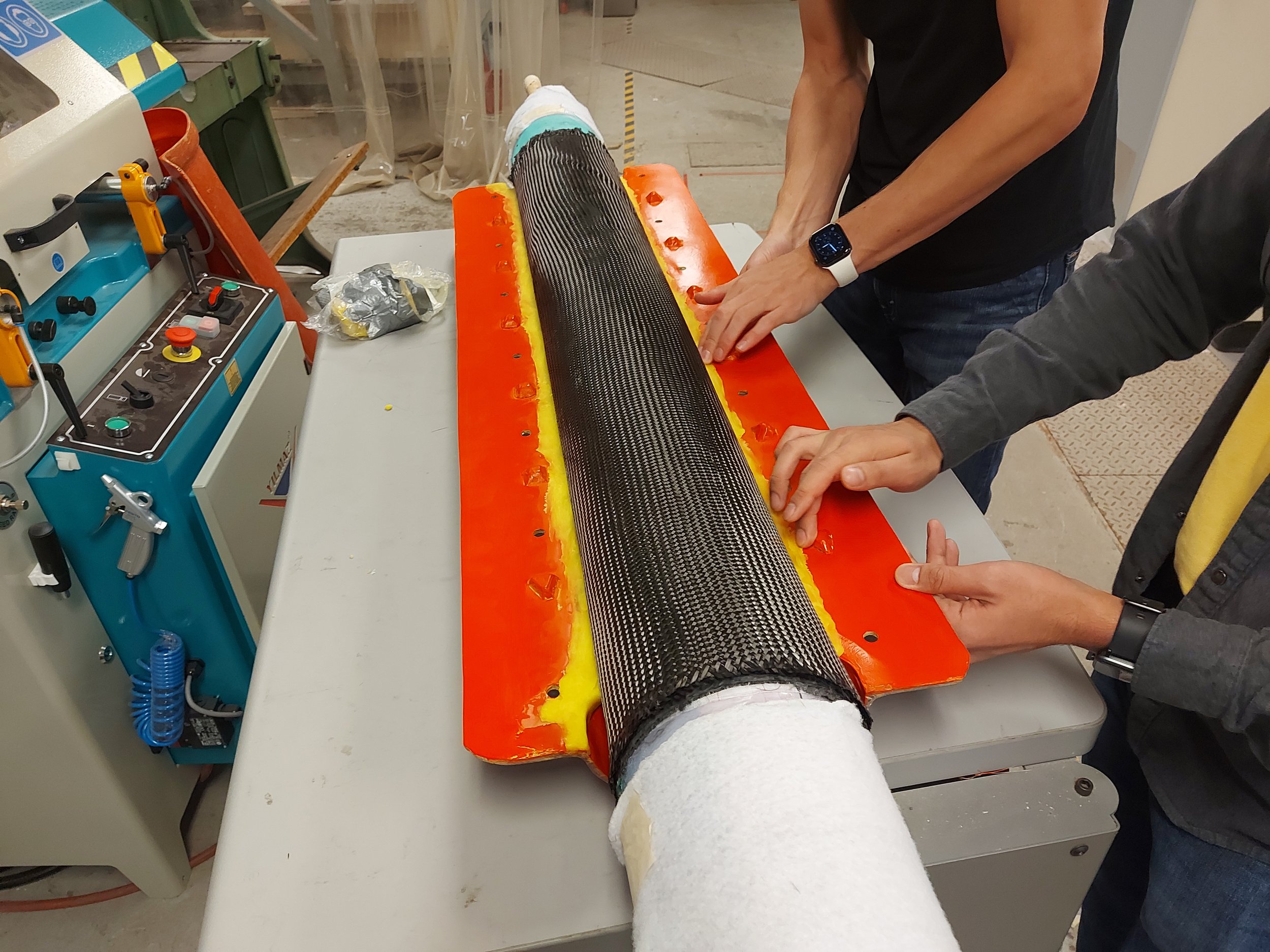

The Aerostructures subteam is in charge of designing, manufacturing and testing the rocket’s airframe. The most important task of the aerostructures crew is to manufacture the rocket’s composite body using VARI (Vacuum-Assisted Resin Infusion) and Prepreg. The subteam is responsible for the integration of all the rocket subsystems as well as for the finishing of the rocket’s exterior. Additionally, we work cross-subteam on jigs and tooling projects such as our recovery drop test rig.

A typical Aerostructures member is

Interested in composite materials (Carbon/Glass Fiber)

Has good design skills

Interested in learning CAD, FEA and CFD

Interested in hands-on work!

Current Projects

Manufacturing of the rocket’s airframe using VARI and Prepreg

Research and Development of our jigs and tooling

Research and Development of composite mould manufacturing techniques